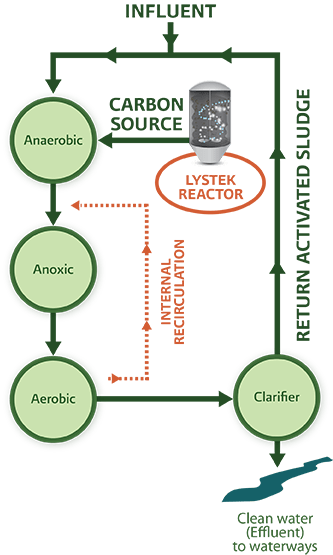

Lystek hydrolyzed biosolids can be used as a safe, cost-effective alternative carbon source for Biological Nutrient Removal (BNR) systems. We call this product LysteCarb®.

LysteCarb Alternative Carbon Source

About LysteCarb

Carbon is required to facilitate the removal of both Nitrogen (N) and Phosphorous (P) in biological nutrient removal (BNR) systems. When WWTPs do not have sufficient organic carbon in their incoming wastewater, a consistent, supplemental source of carbon is used to ensure reliable performance.

Not only does LysteCarb contain a much higher COD:N:P ratio than raw wastewater, but the material is also much higher in concentrations of readily biodegradable COD.

This product can replace costly conventional chemicals such as methanol, glycerol, or acetic acid. When recycled in BNR systems, LysteCarb provides readily available carbon for denitrification and Enhanced Biological Phosphorus Removal (EBPR).

LysteCarb offers enhanced BNR system operations with a safer, cost effective source of carbon for enhanced biological denitrification and phosphorous removal.