The Lystek Package THP solution is Lystek’s smallest commercial system built to date. The units extend the proven advantages of the in-plant Lystek THP solution by offering an award-winning process through a compact, cost effective package capable of rapid implementation.

Lystek Celebrates 25 Years of Innovation

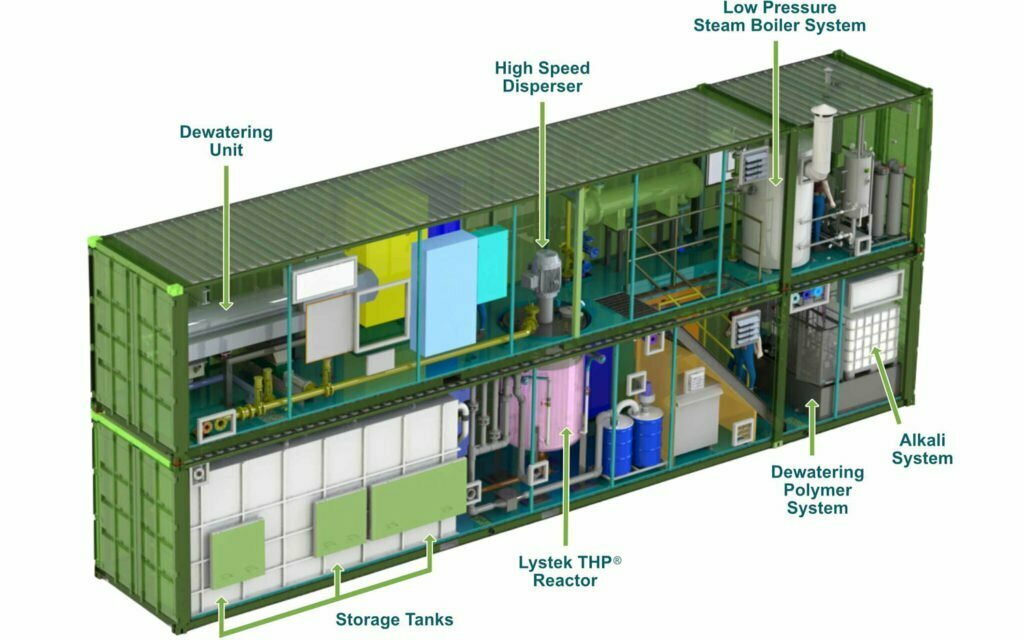

Lystek Package THP

Key Features

- Ease of on-site installation and operation

- Operational flexibility / end product flexibility

- Automated operation, SCADA controlled, remote access available

- Minimal input requirements and external connections

- Potable water, alkali, electricity, recycled water

Modular Design

The system operates entirely within two vertically stacked 50’ containers and requires minimal external utilities. The units come complete with dewatering and capitalizes on Lystek’s modular design to extend the proven advantages of the company’s in-plant Thermal Hydrolysis solutions to a wider range of plant operators.

Operational Flexibility

Lystek Package THP® offers operational flexibility with options for LysteGro® production, LysteMize® digester enhancement, LysteCarb® BNR enhancement, and dewatering capabilities – all included within the unit.

The units are capable of processing 0.3 dry tons per hour. Full technical specifications of this unit are included in our Package THP Technical Specifications Sheet.

Frequently Asked Questions

The ideal site for this unit is a facility that currently generates a liquid residual that can be pumped directly to the unit for dewatering and processing into a high-solids liquid biofertilizer product (LysteGro). Further, if you have an existing low-solids liquid program with storage constraints, transitioning to a LysteGro program can dramatically extend your existing storage capacity due to the notable reduction in volume achieved through the Lystek THP technology. If your site is experiencing storage capacity stress, this approach can provide substantial advantages.

Processing all or a portion of a plant’s volumes would always be at your discretion, based on your operational requirements, committed quantities, and desired hours of operation.

Similar to our in-plant deployments, we will investigate local markets and offer an appropriate product management agreement to market and manage the LysteGro product for you.